TRAFALGAR HOLDINGS GROUP U.S.A. & LATIN AMERICA®

LNG Branch

Welcome to Trafalgar Group, the world’s leading supplier of advanced modular plants for liquefied natural gas (LNG). Our company is committed to providing innovative, reliable, and efficient LNG solutions that meet the ever-evolving needs of the energy industry.

With decades of experience and a team of dedicated professionals, Trafalgar Group has established itself as a trusted name in the LNG industry. Our modular plants are designed to be flexible, scalable, and easy to install, allowing our customers to rapidly expand their LNG production capacity while minimizing downtime and maximizing efficiency.

At Trafalgar Group, we understand the importance of sustainability and environmental responsibility in the energy industry. That’s why our LNG plants are designed to be energy-efficient and environmentally friendly, minimizing emissions and reducing our customers’ carbon footprint.

Our commitment to quality and customer satisfaction is unparalleled. We work closely with our customers to understand their unique needs and provide customized solutions that meet their specific requirements. From initial design and engineering to installation and ongoing maintenance, Trafalgar Group is dedicated to delivering world-class service and support!

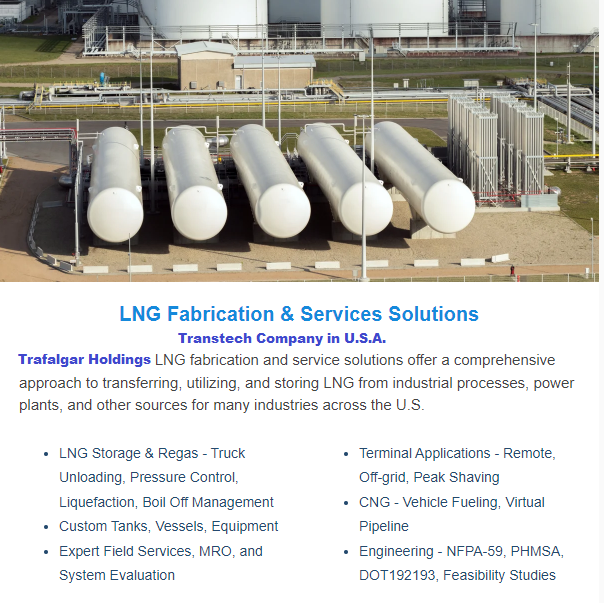

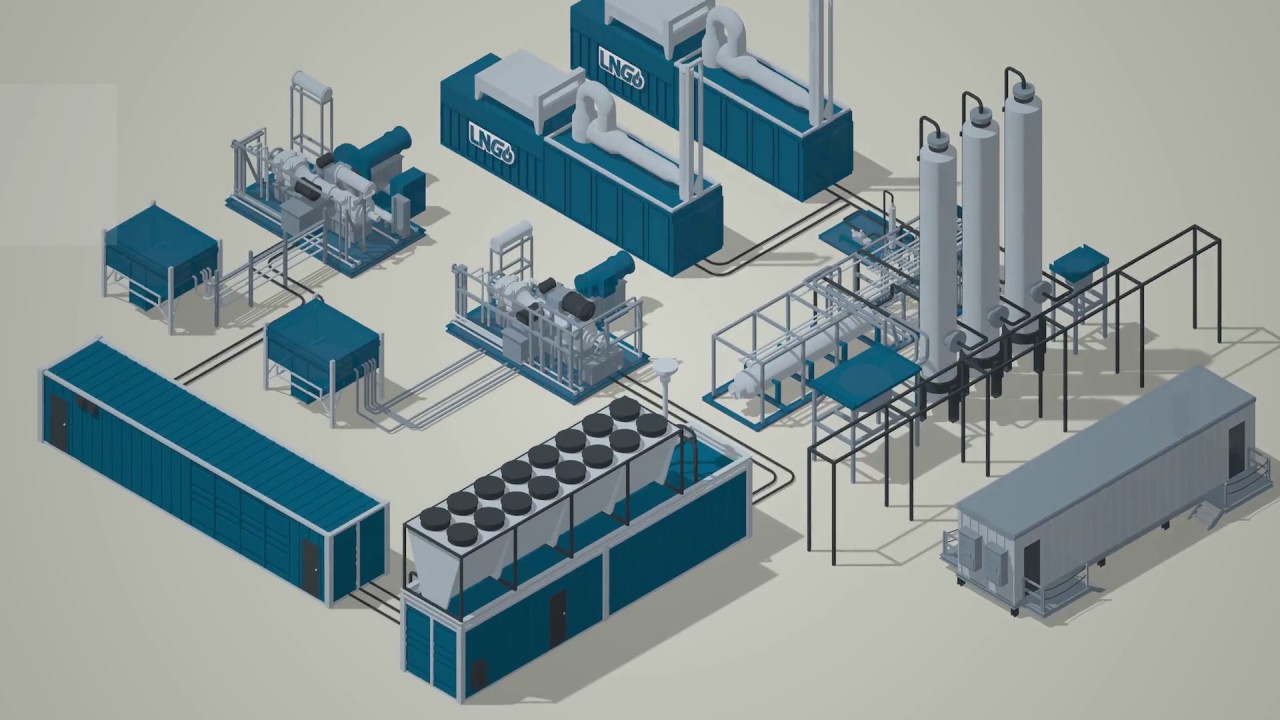

Natural Gas liquefaction on-site innovation. Plants by Siemens & Kinder Morgan U.S.A.

We are experts in LNG and Natural Gas Processing.

We have developed systems that combine advanced engineering whith the highest quality fabrication, allowing us to design, build and execute high performance gas processing solutions faster, more efficiently and more economically than has ever been posible.

We use Innovative, Efficent and Optimized Technology in LNG to provide complete solutions.

Trafalgar Group will install LNG, Gas Treatment plants at Worldwide locations.

The Dresser-Rand business’ LNGo™ natural gas liquefaction system is a Modular, portable natural gas liquefaction plant designed to provide onsite natural gas liquefaction. The low-pressure system is sized to produce approximately 7,000 gallons (26.5 cubic meters) of liquefied natural gas (LNG) per day, while the high-pressure system is sized to produce approximately 30,000 gallons (113.5 cubic meters) per day. It can be used in upstream, midstream and downstream applications.

The pre-packaged system has no external power requirements, minimal site requirements and a streamlined installation process. Inlet natural gas is converted to LNG and used as a process refrigerant, while a small portion of the inlet gas is used to power the plant in conjunction with waste gas. The technology eliminates the need for the costly trucking of LNG long distances from large centralized plants to LNG fueling depots, as is the practice today.

Two LNGo™ natural gas liquefaction systems have already been sold to Elizabeth town Gas, a subsidiary of AGL Resources based in Elizabeth, New Jersey. Elizabeth town Gas provides natural gas delivery service to approximately 283,000 residential, business and industrial natural gas customers in New Jersey. The systems will be sized to produce approximately 13,500 gallons (51 cubic meters) of LNG per day.

Our Manufacturing & Supplying Capabilities

Plant 6000~600,000/GPD Capacity

Gas Treatment Plant 30~90 /GPM

Micro Scale Plants Installed in U.S.A.

Actual Operating Plant Pics

Actual Operating Plant Pics